Phytosanitary Requirements for Imported Fresh Kiwifruit from Greece

I. Basis for Inspection and Quarantine

(I) The Law of the People's Republic of China on Entry and Exit Animal and Plant Quarantine,Regulations on the Implementation of the Law of the People's Republic of China on Entry and Exit Animal and Plant Quarantine;

(II)Food Safety Law of the People's Republic of China, and Regulations on the Implementation of the Food Safety Law of the People's Republic of China.;

(III)Measures for the Supervision and Administration of Inspection and Quarantine of Entry Fruit;

(IV) Protocol Between the General Administration of Customs of the People's Republic of China and the Ministry of Rural Development and Food of the Hellenic Republic on the Phytosanitary Requirements for Kiwifruit Exported from Greece to China.

II. Name of Commodities Permitted for Entry

Fresh kiwifruit; scientific names: Actinidia chinensis and A. deliciosa, common name: kiwi fruit (hereinafter referred to as "kiwifruit").

III. Permitted Origin

Kiwifruit production areas in Greece.

IV. Approved Orchards, Packaging Facilities, and Quarantine Processing Sites

The orchards, packaging facilities, cold storage, and cold treatment facilities for exported kiwifruit to China must be registered upon approval by the Ministry of Rural Development and Food of the Hellenic Republic (hereinafter referred to as 'MRDF') and subsequently reviewed and approved by the General Administration of Customs of the People's Republic of China (hereinafter referred to as 'GACC'). The registration details include the name, address, and identification code. The registration list shall be submitted by MRDF to GACC prior to the start of each export season. In case of changes to the list, MRDF is responsible for promptly providing the updated version to GACC. The GACC website provides access to the approved registration list.

Section V:List of Quarantine Pests of Concern

1. Ceratitis capitata

2. Ceroplastes rusci

3. Hemiberlesia lataniae

4. Hemiberlesia rapax

5. Lobesia botrana

6. Phaeoacremonium aleophilum

7. Pseudococcus longispinus

8. Pseudomonas syringae

9. Verticillium albo-atrum

VI. Pre-export Requirements

(I) Orchard Management.

1. Orchards registered for exporting products to China are required to adopt and implement Good Agricultural Practice (GAP) certification or equivalent international certification systems, ensuring traceability throughout the production process. Ensure the orchard's sanitary conditions by promptly removing fallen fruits and discarding rotten fruits during harvesting. Implement integrated pest management (IPM), comprising pest monitoring, chemical or biological control strategies, and agricultural operations to safeguard crop health.

2. The plant quarantine measures for orchards registered for exporting products to China must be implemented under the supervision of qualified professional and technical personnel. Technicians are required to undergo training provided by MAFF or its authorized training institutions.

3. Orchards registered for exporting products to China are obligated to maintain thorough records of pest monitoring and control measures. These records must be presented to GACC upon request. The documentation for pest control must include comprehensive details such as the name of chemical agents,their active ingredients, application dates, and applied concentrations throughout the growing season.

4. Regarding the Ceratitis capitata, MRDF should establish a comprehensive and continuous monitoring system, employing sex pheromone lures from the flowering stage to the harvest phase of kiwifruit. Regular checks of the traps should be conducted every seven days. MRDF must maintain detailed records concerning the monitoring and supervision activities related to the ceratitis capitata, ensuring their availability for GACC's examination.

5. Regarding the Lobesia botrana, kiwifruit exported to China must originate from non-epidemic production areas or sites jointly approved by MRDF and GACC. MRDF must adhere to the principles of the International Standard for Phytosanitary Measures No. 10 (ISPM10) to establish non-epidemic production areas or sites. MRDF personnel or authorized representatives are required to monitor the presence of the Lobesia botrana throughout the kiwifruit flowering and harvesting stages in registered orchards using visual inspections and traps, maintaining a trap density of one per 0.5 hectares in the specified orchards. MRDF personnel or authorized representatives must inspect traps every 2 weeks and replace the lures every 4 weeks to ensure the absence of the Lobesia botrana in kiwifruit orchards.

Should theLobesia botrana be detected in a previously recognized non-epidemic production area or point, the status of the respective non-epidemic production area or site will be revoked. MRDF must inform GACC within 48 hours and promptly activate the National Emergency Action Plan. After MRDF eradicates the epidemic and receives GACC approval, non-epidemic production regions or non-epidemic production sites may resume operations.

6. Concerning Ceroplastes rusci, orchards registered for exporting products to China should establish a monitoring system and conduct weekly inspections from the flowering to the harvesting period. The examination focuses on identifying target pests on branches, stems, foliage, fruit stalks, and fruits. Should Ceroplastes rusci be detected on kiwifruits, the MRDF must promptly implement measures, such as chemical or biological controls, to manage the pest's incidence.

7. If other quarantine pests of concern to China are discovered, the MRDF must promptly undertake appropriate measures to manage them, ensuring that exported kiwifruit are free of these pests.

(II) Management of Packaging Facilities.

1. The processing, packaging, storage, cold treatment, and shipment of kiwifruit for export to China must be conducted under strict quarantine inspection by MRDF officials.

2. During packaging, kiwifruits shall undergo removal, sorting, and grading to guarantee the absence of insects, mites, decayed fruit, and any stems, leaves, roots, or soil.

3. Kiwifruit exported to China must be independently packaged and stored separately.

(III) Packaging Requirements.

1. Packaging materials used for kiwifruit exported to China must be clean, unused, comply with China's phytosanitary quarantine regulations, and effectively prevent contamination by pests.

2. Each packaging box must display the fruit name, place of production (district, city, or county), country, orchard and its identification number, and packaging facility and its registration number in English.

3. Each packaging box and pallet must clearly display the English indication"Exported to the People's Republic of China." In cases where pallets are not utilized, such as for air shipments, the same labeling is required on each packaging box.

4. If wooden packaging materials are employed, they must adhere to the International Standards for Phytosanitary Measures, specifically ISPM No. 15.

5. Containers loaded with kiwifruit for export to China must be checked for good sanitary conditions before packing.

(IV) Quarantine Treatment Requirements.

1. Kiwifruit exported to China is subject to mandatory cold treatment procedures. The technical requirements for cold treatment are as follows:

| Temperature Range |

Duration in Days |

| 1.1°C or below |

14 |

| 1.7°C or below |

16 |

| 2.1°C or below |

18 |

Note: The aforementioned temperatures indicate the core temperature of the fruit.

2. Cold treatment must be conducted under the supervision of MRDF officials following procedures for cold treatment prior to export (Annex 1) or procedures conducted during transport to the exporting country (Annex 2).

(V) Pre-export Quarantine.

1. MRDF officials or personnel authorized by MRDF shall perform a sampling inspection of each batch of kiwifruit exported to China at a rate of 2%. If no phytosanitary issues occur over a two-year period, the sampling rate may be reduced to 1%.

2. If any live quarantine pests of concern to China are found, the entire shipment cannot be exported to China. MRDF must identify the cause and implement corrective measures. Concurrent with this, maintain the detection records for provision to GACC upon request.

(VI)Requirements for Phytosanitary Certificate.

1. Upon satisfactory quarantine inspection, the MRDF shall issue a phytosanitary certificate specifying the container number and including the following additional statement:"This consignment is in compliance with the requirements specified in the Protocol of Phytosanitary Requirements for Kiwifruit Exported from Greece to China, and is free from quarantine pests of concern to China."

2. If pre-export cold treatment is conducted, the phytosanitary certificate must specify the method of cold treatment, the treatment temperature, duration, and the name or identification number of the treatment facility. If cold treatment is conducted during transit, the phytosanitary certificate must indicate "cold treatment in transit" and list details such as the treatment temperature, duration, container number, and seal identification number.

3. Prior to the commencement of export, the MRDF shall provide the GACC with a sample of the phytosanitary certificate to facilitate filing and verification by the Chinese authorities.

VII. Entry Inspection and Quarantine and Handling of Non-conformities

When the kiwifruit arrives at the port of entry in China, the GACC will conduct quarantine following the specified requirements.

(I) Verification of Relevant Certificates and Marks.

1. Verify whether the imported kiwifruit has obtained the Entry Animal and Plant Quarantine Permit.

2. Verify whether the phytosanitary certificate complies with Article VI, Paragraph (VI).

3. Verify whether the markings on the packaging box meet the requirements outlined in Article VI, Paragraph (III).

4. For goods that underwent cold treatment before export, verify the cold treatment result report and fruit temperature probe calibration record signed and confirmed by MRDF. For goods cold-treated during transportation, verify the cold treatment report, fruit temperature probe calibration record, and related documents.

(II) Entry Inspection and Quarantine.

1. Kiwifruit intended for export to China can be imported through any GACC-approved ports for fruit importation.

2. According to relevant laws, administrative regulations, and provisions, imported kiwifruit will undergo inspection and quarantine. If they meet the required standards, they will be granted entry into China.

(III) Management of Non-conformities.

1. If the origin is determined to be an unapproved orchard, the batch of kiwifruit will be prohibited from entering the country.

2. If the cold treatment is deemed ineffective, the batch of goods will be subject to reevaluated cold treatment at the port (if verified as a cold treatment container, it may continue processing within the same container), return, destruction, or other specified measures.

3. If live quarantine pests of concern to Chinese authorities are identified, the batch of goods will be either returned or destroyed. Simultaneously, GACC will promptly notify MRDF, requesting an immediate suspension of kiwifruit exports from the associated orchards to China, and potentially extending this suspension to the entire scheme based on further developments. MAFF shall initiate an investigation to identify the causes and implement relevant corrective actions. GACC will determine the feasibility of lifting the suspension based on the assessment outcomes of the corrective measures implemented by MRDF.

4. If other quarantine pests or any pests previously unreported in China are detected, the affected batch will be subjected to return, destruction, or quarantine-based disinfection treatment. MAFF shall initiate an investigation to identify the causes and implement relevant corrective actions.

VIII. Retrospective Review

GACC will continue conducting additional risk assessments in response to the dynamic developments of the Greek kiwifruit epidemic and interception findings. It will collaborate with the MRDF to revise the list of quarantine pests of concern to China and adjust corresponding quarantine measures accordingly. To ensure the effective implementation of relevant risk management measures and operational requirements, GACC will conduct retrospective reviews every five years following the commencement of trade, assessing the compliance with kiwifruit inspection and quarantine requirements, which include dispatching experts to visit Greece for evaluations.

Operation Procedure for Pre-Export Cold Treatment

1. Cold Treatment Facilities

1.1 Pre-shipment cold treatment is permissible solely within cold treatment facilities approved by both MRDF and GACC.

1.2 MRDF officials hold responsibility for guaranteeing that the cold treatment facilities employed by exporters adhere to the appropriate standards and feature refrigeration equipment capable of achieving and maintaining the requisite fruit temperatures.

1.3 MRDF officials shall maintain registration records of facilities approved for pre-shipment cold treatment of kiwifruits intended for export to China, accompanied by documentation specifying the following details:

(a) The respective locations and architectural layouts of all facilities, along with detailed contact information of their owners/operators;

(b) The dimensions and capacity of the facility;

(c) Insulation specifications for walls, ceilings, and floors;

(d) Brand, design, type, and capacity details of refrigerant compressors and evaporators/air circulation systems;

(e) Temperature range of the equipment, the specifications and details of defrost cycle control, and any integrated temperature recording devices.

1.4 Prior to the commencement of each kiwifruit export season, MRDF shall provide to GACC the name and address of the currently registered cold treatment facilities.

2. Recorder Type

MRDF officials shall ensure that the combined use of temperature probes and recorders meets the following specifications:

(a) Operates within a range of -3.0°C to +3.0°C, with an accuracy of ±0.15°C;

(b) Capable of accommodating the required quantity of probes;

(c) Capable of recording and storing process data until verified by MRDF officials;

(d) Capable of recording data for all probes at least once per hour with the necessary accuracy;

(e) Generates a print-out identifying the time and temperature of each probe and indicates the identification numbers of the recorder and container.

3. Temperature Calibration

3.1 Calibration must be conducted using a standard thermometer approved by MRDF officials in a mixture of crushed ice and distilled water.

3.2 Any probe showing a reading outside the range of 0°C ± 0.3°C must be replaced.

3.3 Upon completion of the procedure, MRDF officials will confirm the calibration accuracy of the fruit temperature probe employing the methodology detailed in Paragraph 3.1.

4. Placement of Temperature Probes under the Supervision of MRDF Officials

4.1 Palletized fruits must undergo pre-cooling and subsequent transfer to the cold treatment room under the oversight of MRDF officials, though pre-cooling may alternatively be performed independently by the exporter.

4.2 Employ at least two probes (positioned at the air outlet and the return air inlet) for room temperature monitoring. Additionally, insert a minimum of the following four probes to gauge the temperature of fresh fruits:

(a) A probe placed at the center of the cargo positioned in the midsection of the cold treatment room;

(b) A probe placed at a corner on the topmost layer of cargo in the midsection of the cold treatment room;

(c) A probe placed in the midsection of the cargo near the return air inlet connection;

(d) A probe placed at a corner on the topmost layer of the cargo near the return air inlet connection.

4.3 The placement of the probe and its connection to the recorder must be performed under the supervision and guidance of MRDF officials.

4.4 Recording may commence at any time; however, the processing duration can only be calculated once all fruit temperature probes achieve the specified temperature.

4.5 When using the minimum number of probes, if any probe continuously fails for over four hours, the treatment is considered invalid and must be restarted.

5. Step-by-Step Review of Treatment Results

5.1 If the treatment record indicates compliance with the required parameters, the MRDF officials may authorize the completion of the treatment. Furthermore, if the probe has been successfully calibrated in accordance with "Paragraph 3", the treatment can be deemed as having been successfully completed.

5.2 The probe must undergo calibration before the fruit is removed from the treatment chamber.

6. Confirmation of Treatment Results

6.1 Upon completing the designated treatment time, the probe must be recalibrated in conformity with "Paragraph 3" procedures. Calibration records should be preserved and made available for review by GACC if required.

6.2 If the calibrated reading of the probe(s) upon completion of the procedure exceeds the initial calibrated reading, the recorded readings of the probe(s) must be adjusted accordingly. If the adjustments indicate non-compliance with the specified treatment protocol, the treatment will be deemed invalid. MRDF officials, in coordination with exporters, will decide whether to reprocess the concerned batch of fruits.

6.3 The temperature record printouts must include comprehensive statistical data demonstrating the completion of the cold treatment.

6.4 Prior to confirming successful treatment, MRDF officials must verify the aforementioned records and statistical data; upon request by GACC, these verified records must be made available for review.

6.5 If the treatment does not satisfy the specified cold treatment criteria, the recorder may be reconnected to continue treatment under the following conditions:

(a) MRDF officials confirm that the conditions outlined in Paragraph 6.3 are still being met;

(b) The interval between when the process stopped and when it was resumed is less than 24 hours.

In either case, data collection may resume from the moment the recorder is reconnected.

7. Container Loading

7.1 Prior to loading, containers must be inspected by MRDF officials to ensure they are free from pests and secured at the entrance to prevent pest entry.

7.2 Fruits must be packed either within insect-proof facilities or by surrounding the entrance of cold storage rooms and the containers with insect-resistant materials.

8. Container Sealing

8.1 MRDF officials will apply coded seals to loaded containers, with the seal number recorded on the phytosanitary certificate.

8.2 Seals may only be removed by Chinese customs officers at the ports of entry in China.

9. Storage of Fruits Not Packed Immediately

9.1 Treated fruits may be stored without immediate packing, but safety conditions must be ensured by MRDF officials:

(a) If stored within a treatment room, the room’s doors must remain sealed;

(b) If transported to another storage room, such transfer must be conducted securely as approved by the MRDF, and no other fruits may be present in the same storage room;

(c) Subsequent packaging must be conducted under the supervision of MRDF officials in accordance with the regulations outlined in Paragraph 7.

10. Phytosanitary Certificate

10.1 The pre-export cold treatment's temperature, duration, and the responsible facility's name or number must be clearly stated in the treatment section of the phytosanitary certificate.

10.2 Upon the entry of kiwifruit into China, the plant quarantine certificate along with a cold treatment results report must be submitted to the Chinese Customs. This report must include temperature records confirmed and signed by MRDF officials along with calibration records of the fruit temperature probes.

Operational Procedure for Cold Treatment during Transportation

1. Container Type

The container must be a self-refrigerated (integral) transportation unit equipped with a refrigeration system capable of achieving and maintaining the required temperature conditions.

2. Recorder Type

MRDF officials must ensure the use of an appropriate combination of temperature probes and recorders:

2.1 The probe's temperature must measure between -3.0°C and +3.0°C with an accuracy of ±0.15°C.

2.2 A sufficient number of probes shall be deployed.

2.3 The equipment must be capable of recording and storing data throughout the treatment process.

2.4 Document the temperature of all probes at least once per hour, ensuring the records demonstrate adherence to the accuracy specifications of the probes.

2.5 The printed temperature records must detail the time and temperature for each probe, and indicate the recorder and container identification number.

3. Temperature Calibration

3.1 Calibration must be conducted using a standard thermometer approved by MRDF officials in a mixture of crushed ice and distilled water.

3.2 Any probe with a reading deviating beyond 0°C±0.3°C must be replaced.

3.3 A "Fruit Temperature Probe Calibration Record" signed and stamped by an MRDF official must be issued for each container. The original document must accompany the phytosanitary certificate.

3.4 Upon arrival at the port of entry in China, customs officers will perform calibration and inspection of the fruit temperature probes.

4. Placement of Temperature Probes

4.1 The packaged fruits must be loaded into the transportation container under the supervision of MRDF officials. The packages should be stacked loosely to ensure adequate airflow gaps;

4.2 Each container must have at least 3 fruit temperature probes and 2 space temperature probes placed. Their specific locations are:

(a) The No. 1 fruit temperature probe is placed in the center of the top layer of the first row of goods within the container;

(b) The No. 2 fruit temperature probe is placed at a distance of 1.5 meters (for a 40-foot container) or 1 meter (for a 20-foot container) from the container door center, and at half the height of the cargo;

(c) The No. 3 fruit temperature probe is placed on the left side of the container door at a distance of 1.5 meters (for a 40-foot container) or 1 meter (for a 20-foot container), and at half the height of the cargo;

(d) Two space temperature probes are respectively placed at the air inlet and the return air outlet of the container.

4.3 All probes must be placed under the oversight and direction of MRDF officials.

4.4 Fruits must be stored (pre-cooled) in a refrigerated environment prior to loading until their pulp temperature reaches 4°C or below.

5. Container Sealing

5.1 Containers filled with goods shall be sealed with coded seals by MRDF quarantine officers.

5.2 Seals may only be removed by customs officers at Chinese entry ports.

6. Verification of Treatment Results

6.1 Should the treatment records demonstrate compliance with technical standards, the GACC is to authorize the conclusion of the treatment process. Furthermore, if the probes conform to the criteria stipulated in Paragraph 3, the treatment will be considered compliant.

6.2 The probe must undergo calibration before the fruit is removed from the container.

7. Temperature Recording and Confirmation

7.1 Cold treatment during transport refers to the process conducted on containers carrying fruits, beginning during their shipment from Greece to the first Chinese port of arrival or extending to the port of entry.

7.2 Recording may commence at any time; however, the calculation of treatment duration is officially initiated only when all fruit temperature probes have reached the prescribed temperature.

7.3 The shipping company must download the cold treatment temperature records and submit them to Chinese Customs at the port of entry.

7.4 On certain voyages, the cold treatment may be completed before the vessel's arrival at a Chinese port. In such cases, downloading the treatment records and transmitting them to Chinese Customs en route is permissible for evaluation.

7.5 Customs will verify whether the treatment records align with the specified processing requirements and evaluate the treatment's validity based on the probe calibration results.

8. Phytosanitary Certificate

8.1 The temperature, treatment duration, container number,and seal identifier of the cold treatment must be clearly stated in the phytosanitary certificate, and marked as 'in transit'.

8.2 When kiwifruit is imported, a phytosanitary certificate, cold treatment report, and fruit temperature probe calibration record must be presented to Chinese Customs.

Disclaimer:The above content is translated from Chinese version of GACC. The GACC version shall prevail.

Related News

First “Rail-Sea-Rail” Multimodal Transport Train Launched from Beijing-Tianjin-Hebei Region to Greece

2025-11-05

The Beijing-Tianjin-Hebei region inaugurated its first “rail-sea-rail” multimodal transport train to Port of Piraeus in Greeceon October 28, with the train departing from Shijiazhuang International Dry Port.

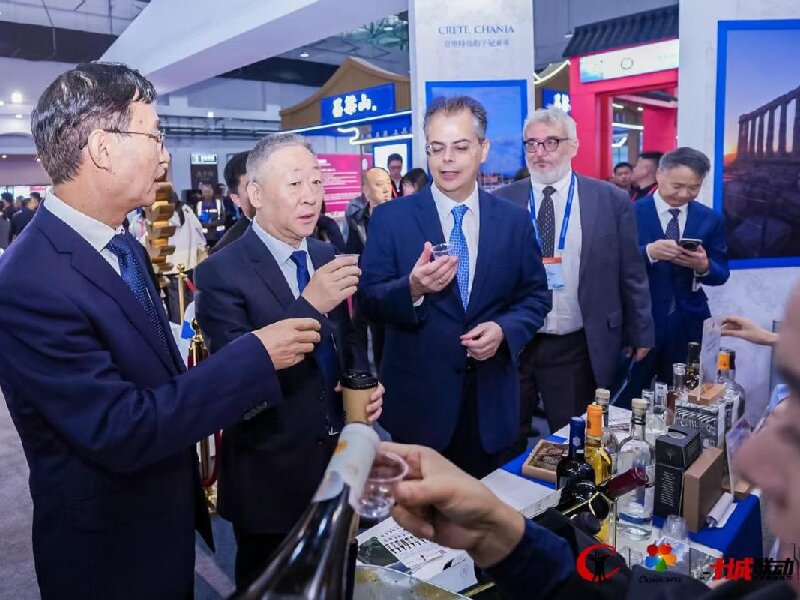

Greece shares flavor of top alcoholic exports at expo

2025-10-09

The expo, which runs until to Oct 1, has attracted nearly 500 domestic and foreign producers of alcoholic beverages and companies that make equipment and packaging material, significantly raising its profile on the international stage.

Fang Qiu, Ambassador to Greece, Attended the Signing Ceremony of Protocol on Greek Aquatic Product Exports to China

2025-02-26

On February 17, 2025, Li Kuiwen, Party Committee Member of China's General Administration of Customs and Director of Guangdong Sub-administration, signed the Protocol on Inspection, Quarantine and Veterinary Health Requirements for Export of Wild and Cultured Aquatic Products from Greece to China with Kostas, Deputy Minister of Agricultural Development and Food of Greece, in Athens.

Hot News