Do You Understand Imported Recycled Copper Raw Materials and Copper Alloy Raw Materials?

Issue Date:2024-12-25

Copper possesses excellent electrical conductivity, thermal conductivity, and ductility, making it an essential metal for numerous industries. Furthermore, its stable chemical properties allow it to be recycled multiple times without losing its inherent qualities. Consequently, the reuse of recycled copper is a significant source of copper raw materials.

Next, let's explore the relevant aspects of importing recycled copper raw materials and copper alloy raw materials from abroad.

I. Definitions and Classifications

Recycled copper raw materials are defined as copper materials that, after classification and preprocessing, meet the requirements for direct production use.

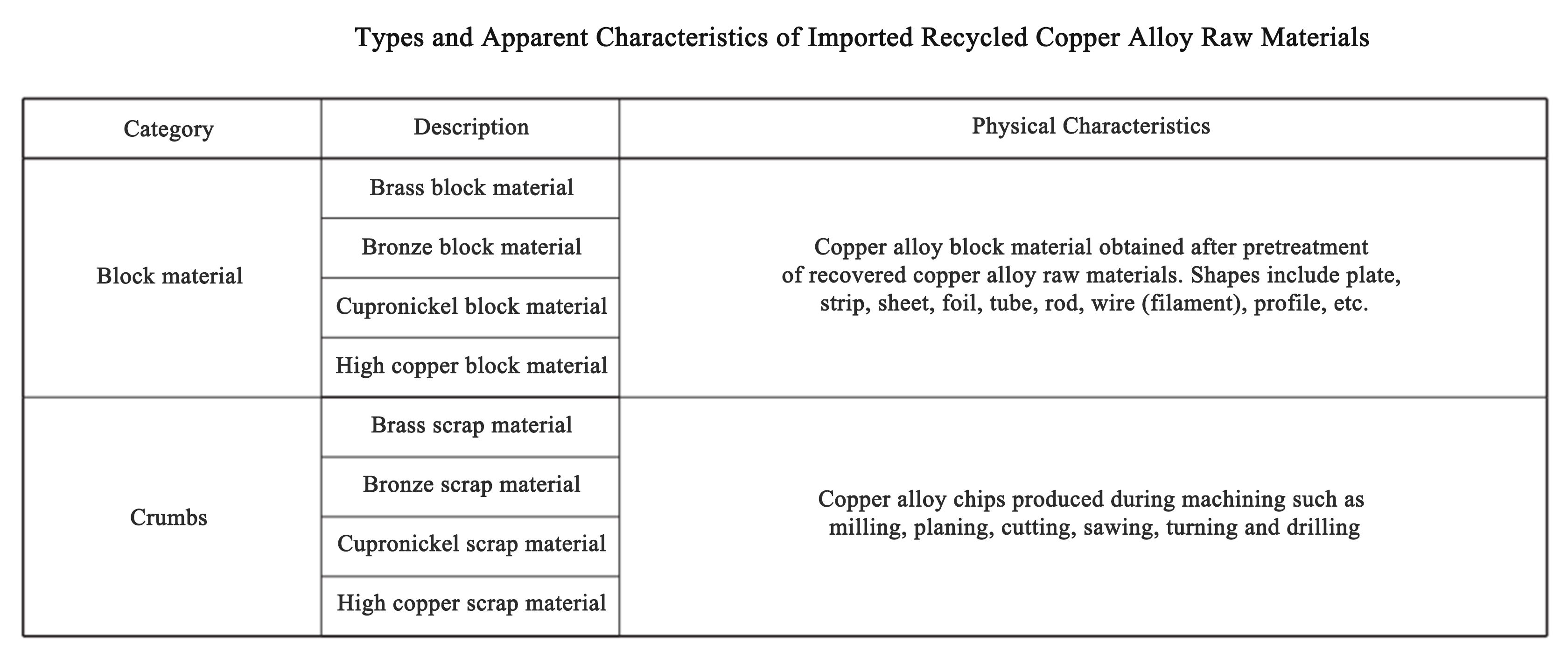

Recycled copper alloy raw materials are defined as recycled copper alloy materials (such as brass, bronze, white copper, high-copper alloys, etc., which are copper-based alloys with one or more added elements to achieve specific predetermined characteristics) that, after classification and preprocessing, meet the requirements for direct production use.

Imported recycled copper raw materials and copper alloy raw materials can be categorized into the following types based on their physical characteristics:

.png)

II. Customs Supervision

In November 2024, the General Administration of Customs issued the Inspection Regulations for Imported Recycled Copper Raw Materials (SN/T5416-2024) and the Inspection Regulations for Imported Recycled Copper Alloy Raw Materials (SN/T5417-2024), which outline the overall requirements, on-site inspections, sampling procedures, and result handling for imported recycled copper raw materials and copper alloy raw materials.

1. Overall Requirements

Inspection Location: In principle, customs should carry out inspections of imported recycled copper raw materials and copper alloy raw materials at the first port of entry. GACC may designate other inspection locations as needed to facilitate foreign trade and import/export commodity inspection activities.

Shipping Requirements: Imported recycled copper raw materials and copper alloy raw materials should not be mixed with other types of imported recycled metal raw materials. Different categories of bulk raw materials should not be combined. If different categories of raw materials are individually packaged, they may be mixed during shipping but must be kept separated.

Documentation Requirements: Under the same customs declaration, declaring different types of recycled raw materials is not permitted. The declaration details must adhere to standard requirements and clearly specify the exact raw material categories. The container number (or other vehicle identification numbers) and seal numbers must correspond with the information listed in the relevant documentation.

2. On-site Inspection

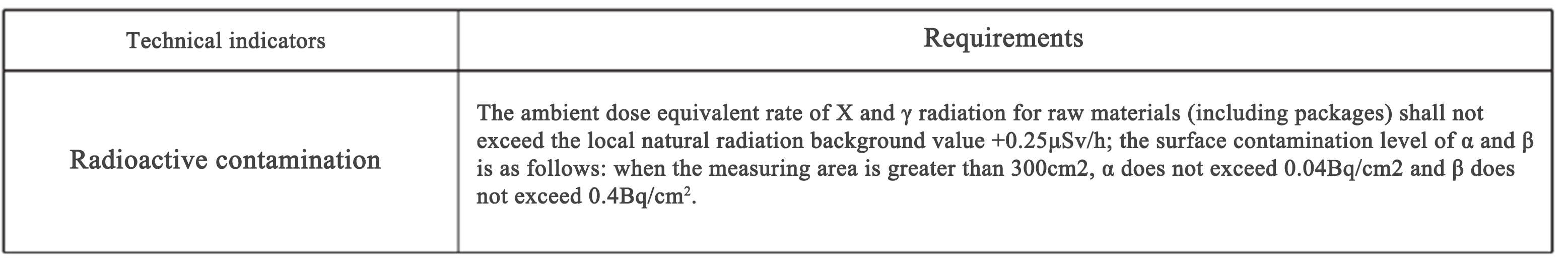

Radiation Contamination Inspection:

Radiation contamination inspections are carried out using fixed radiation monitoring equipment such as portal radiation detectors or through manual patrol methods. The required results are outlined in the table below:

Prohibited Substances:

The raw materials must not contain discarded bombs, shells, or other explosive items, nor should they include sealed containers, pressure vessels, or similar objects.

Hazardous Waste Requirements:

The mass of hazardous waste in the raw materials must not exceed 0.01% of the total mass of the raw materials (mass fraction).

Impurity Requirements:

Impurity content must be ≤0.8% (mass fraction).

Physical Quantity Requirements for Copper Raw Materials and Copper Alloy Raw Materials:

1) For recycled copper raw materials, the physical copper content must be ≥97.0% in copper wire, ≥97.0% in mixed copper materials, and ≥98.0% in copper dross.

2) For recycled copper alloy raw materials, the physical copper content in copper alloys must be ≥95.0%.

(The above requirements are all based on mass fraction)

Requirements for Raw Materials Containing Non-Metallic Coatings:

The mass should not exceed 5% of the total mass of the raw materials.

Additionally, customs will perform visual inspections to assess the apparent characteristics of the raw materials and to determine whether they are suspected of being solid waste.

IV. Result Handling

1. If all inspection items carried out according to the control instructions pass, the batch of raw materials will be deemed qualified and released.

2. If any one of the inspection results for radioactive contamination, explosive items, sealed containers, pressure vessels, hazardous waste, apparent characteristics, impurity content, physical copper content or physical copper alloy content, or raw materials containing non-metallic coatings fails, the batch of goods will be deemed unqualified and handled as follows:

a) If any one of the inspection results for radioactive contamination, explosive items, or hazardous waste fails, handle them in accordance with relevant regulations or implement re-export.

b) If any one of the inspection results for sealed containers, pressure vessels, impurity content, physical copper content or physical copper alloy content, or raw materials containing non-metallic coatings fails, implement re-export handling in accordance with relevant regulations.

c) If the apparent characteristics fail due to a classification declaration error but meet shipping requirements, handle them according to relevant declaration regulations. For other cases of failed apparent characteristics, implement re-export handling in accordance with relevant regulations.

3. If identified as solid waste by a professional institution, handle it in accordance with relevant solid waste regulations.

Disclaimer:The above content is translated from Chinese version of this website. The Chinese version shall prevail.